Tubular Level Gauges

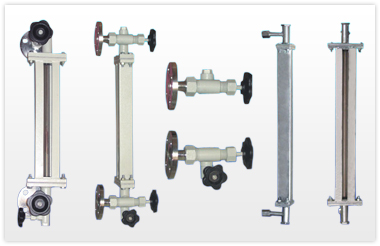

Utilising the basic principle of - liquids find their level - tubular level gauges have been the most preferred and economical means of direct liquid level indication since time immemorial. Various means of glass tube protections- 3 plate glass protection, 3 guard rods, pipe guard or C-channel protections are in popular use. Our level gauges have C-channel protection of 2 mm thick sheet metal, making it robust and sturdy.

A black powder coated aluminium engraved scale with white numerals & markings is provided for indication of the level of liquid in millimeter or Litres as required. Scale shall have minimum graduation of 5 mm.

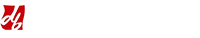

Process connections can be threaded or flanged to customer specifications. Isolating cock valves/needle valves or isolating needle valves with safety ball-check protection to prevent spilling/leakage by automatic shut-off in the event of glass tube breakage- are optional features

Technical Specification

| Process Connection | Threaded or Flanged |

|---|---|

| Connection Size | 1/2" or 3/4" BSP(M) or Flanged to 3/4" or 1" ASA 150 Lbs as standard (Please specify other connections ,if required) |

| End Connection MOC (Wetted Parts) | Mild Steel Grey powder coated / Chromium plated MS / SS 304 / SS316 / PVC/ FRP |

| Gauge Glass | 19 mm H/W borosilicate glass tube. |

| Glass Tube Protection | C-Channel of Grey powder coated or Chromium plated MS / SS304 / FRP Or SS316. (Size: 45x65x2mm) |

| Flange Gaskets | CAF-Acid alkali style 60 |

| Scale | Black powder coated aluminium with white numerals & markings. |

| Vent& Drain Plugs | 1/2"BSP(M) |

| Bolts & Nuts | HT bolts & nuts/SS 304 |

| Maximum working pressure-10 kg/sq.cm (depends on length) | |

| Maximum working temperature-100 deg C (Maximum length in single piece-2500 mm) | |

Optional Acceessories :

- Vent Cock Valve/Drain Cock/Vent & Drain Needle/Ball Valves

- Gauge Isolating Needle Valves.

- Gauge isolator valve: SS 304/316 solid barstock needle valve,offset type with safety ball-check protection and process connection as above (please specify).